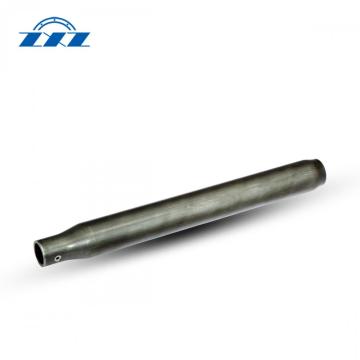

Low friction Low Roughnes Airbag Generator Steel Tube

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 10000 Set/Sets |

| Delivery Time: | 60 Days |

| Packaging: | Industrial package |

|---|---|

| Productivity: | 1000000 |

| Brand: | ZXZ |

| Transportation: | Ocean,Air |

| Place of Origin: | China |

| Supply Ability: | 10000000 |

| Certificate: | ISO9001,ITAF16949;ISO14001; OHSAS18000 |

| Port: | Ningbo Port,ShangHai |

Basic Info

Model No.: Safe Air-bag Tube

Click on the follow link to find out more information: https://www.xccbearing.com/safe-air-bag-tube/

Company Info

- Company Name: ZHEJIANG XCC GROUP CO.,LTD.

- Representative: ZHANGFENG

- Product/Service: Automotive Bearings , Auto Parts , Precision Bearings , Alternator Bearings , Tripod Universal Joint Bearings , Drive Shaft Bearings

- Capital (Million US $): 1700000000

- Year Established: 1968

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 160

- No. of R&D Staff: 61 -70 People

- No. of QC Staff: Above 100 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): Above 100,000 square meters

- Factory Location: No.199,TaiTan Road,XinChang,ZheJiang,China.

- Contact Person: Mr. Peter Ying

- Tel: 86-0575-86013068

Premium Related Products

Other Products

Hot Products

China manufacturer silent type 1200kw generator set approved by CE750kva Open type of electric power generatorSave your fuel,Original 1106A-70TAG3 140KW 175KVA electrical generatorWater cooled 150kw stamford alternator generator with good quality and factory priceHigh price ratio 450KVA Scania diesel generating setBrand New 20KVA YUCHAI Open type Diesel Generator Setstrailer/mobile diesel generator powered by Cummins30KVA Silent Small Marine GeneratorEnergy convasation 50kw gas generator set manufacturerHigh efficiency diesel generator set powered by Volvo Penta manufacturerHigh precision 1800KVA MTU diesel generator set wholesaleChinese generator setDeutz diesel generatorhousehold diesel generator set300KVA Diesel Generator Powered By Cummins For Sale250KVA Silent Diesel Genset with CE certificate